1000KG/H QOS YAJ YWM QOS YAJ YWM FRENCH FRIES UA TSHUAB QOS YAJ YWM

1. Siv zog tsawg, tso zis siab

Qhov kev siv tshuab ua haujlwm tau zoo heev, thiab kev ua haujlwm tau zoo dua qub. Cov qos kib ua tau zoo ib yam, siv tsawg dua, saj zoo ib yam, tsis yooj yim hloov xim, khaws cia cov khoom noj khoom haus zoo, txuag hluav taws xob thiab tiv thaiv ib puag ncig.

2. Kev Noj Qab Haus Huv thiab Kev Nyab Xeeb

Txhua yam khoom siv (qhov chaw sib cuag nrog cov ntaub ntawv) yog ua los ntawm cov hlau tsis xeb, yooj yim ntxuav thiab huv si.

3. Khiav du

Cov khoom siv hluav taws xob ntawm tag nrho lub tshuab yog txhua lub npe nrov uas tau dhau qhov kev xeem ua lag luam, nrog kev lees paub zoo, tus nqi tsis ua haujlwm tsawg thiab lub neej ua haujlwm ntev.

4. Kho kom haum

Raws li lub rooj cob qhia ntawm cov neeg siv khoom, kuj muaj cov kev pabcuam tshwj xeeb rau cov kev xav tau ntau lawm.

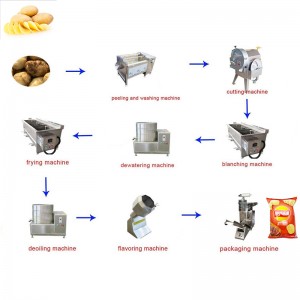

Kev faib tawm thiab kev qhia tshwj xeeb ntawm cov kab ntau lawm kib fries sai:

Qos yaj ywm nyoos → Lub tshuab nqa khoom → Tshuab ntxhua khaub ncaws thiab tev tawv → Kab xa khoom sib cais → Tshuab nqa khoom → Tshuab txiav → Tshuab ntxhua khaub ncaws → Tshuab ua kom dawb → Tshuab txias → Tshuab tshem dej → Tshuab kib → Tshuab tshem roj → Kab xa khoom saib → Lub tub yees qhov av → Tshuab ntim khoom tsis siv neeg

Cov txheej txheem tseem ceeb ntawm cov kab ntau lawm kib kib sai sai tau piav qhia luv luv raws li hauv qab no:

(1) Kev teeb tsa cov khoom siv raw Ua ntej Yuav kom txuas ntxiv lub voj voog ua tiav, cov khoom siv raw qos yaj ywm yuav tsum khaws cia ntev. Tom qab khaws cov khoom siv raw mus ntev, lawv cov qab zib thiab cov khoom noj khoom haus yuav hloov pauv mus rau qee qhov. Yog li ntawd, yuav tsum muaj ib lub sijhawm kho kom rov zoo ua ntej ua tiav kom cov khoom xyaw ntawm cov khoom siv raw ua tau raws li qhov yuav tsum tau ua.

(2) Kev ntxuav kom huv yog feem ntau yog tshem tawm cov av nkos thiab cov khoom txawv teb chaws ntawm qhov chaw ntawm cov khoom siv qos yaj ywm.

(3) Tshem tawm thiab cais cov tawv qos yaj ywm thiab tsuag cov tshuaj tiv thaiv xim kom tiv thaiv kev hloov pauv xim av ntawm cov qos yaj ywm uas tau tev tawm.

(4) Txiav Cov qos yaj ywm uas twb muab tev lawm raug txiav tes kom tshem tawm cov tawv qos yaj ywm uas tsis tau tshem tawm, qhov muag ntawm cov paj, qhov tsis sib luag thiab qhov ntsuab.

(5) Txiav ua tej daim nyias nyias Raws li cov lus qhia sib txawv, txiav cov qos yaj ywm ua tej daim plaub fab, thiab cov daim nyias nyias yuav tsum huv si thiab ncaj.

(6) Kev sib cais ua feem ntawm cov kab luv luv thiab cov khib nyiab uas tsim tawm thaum lub sijhawm ua tiav los txhim kho cov txiaj ntsig.

(7) Kev ziab thiab ziab siv lub tshuab ziab thiab ziab kom tshem tawm cov dej noo ntawm cov qos kib thiab npaj rau cov txheej txheem kib tom ntej.

(8) Cov qos yaj ywm kib yog kib hauv roj kub rau lub sijhawm luv luv, tom qab ntawd muab cov roj ntau dhau tso rau hauv, thiab cov roj ntau dhau raug lim tawm, yog li ntawd cov ntxhiab tsw qab ntawm cov qos yaj ywm kib tuaj yeem kib tau.

(9) Cov qos kib uas khov sai sai tau ua ntej txias thiab xa mus rau cov khoom siv khov sai rau kev khov tob thiab khov sai, yog li ntawd cov crystallization hauv cov qos kib yog sib xws, uas yooj yim rau kev khaws cia ntev thiab khaws cia cov saj qub.

(10) Kev txias hauv hnab tuaj yeem ua tau los ntawm tes lossis los ntawm cov khoom siv tsis siv neeg. Thaum lub sijhawm ntim khoom, lub sijhawm yuav tsum luv dua li sai tau kom tsis txhob nqus dej thiab yaj cov qos yaj ywm kib uas khov sai, uas yuav cuam tshuam rau qhov zoo ntawm cov khoom. Khaws cia rau hauv lub tub yees tam sim ntawd tom qab ntim khoom.

1. Lub tshuab nqa khoom - kev nqa thiab thauj khoom tsis siv neeg, yooj yim thiab ceev, txuag cov neeg ua haujlwm.

2. Tshuab ntxhua khaub ncaws thiab tev tawv - ntxuav thiab tev tawv qos yaj ywm tsis siv neeg, txuag hluav taws xob.

3. Txoj kab xa khoom faib ua pawg - tshem tawm cov qos yaj ywm uas lwj thiab muaj qhov kom zoo dua.

4. Cutter-hloov kho qhov loj me.

5. Ntxuav-Ntxuav cov hmoov txhuv nplej siab rau ntawm qhov chaw ntawm cov qos yaj ywm kib.

6. Tshuab Blanching - inhibit qhov kev ua ub no ntawm cov enzymes nquag, thiab tiv thaiv cov xim.

7. Lub tshuab nce thiab txias - txias cov qos yaj ywm kib sai sai thiab tswj cov xim thiab saj.

8. Lub tshuab rho dej tawm - qhov cua txias ua rau cov qos yaj ywm uas tseem ntub dej tawm ntawm qhov chaw, thiab thauj mus rau lub tshuab kib.

9. Tshuab kib - kib rau xim, thiab ua kom zoo dua cov qauv thiab saj.

10. Tshuab tshem roj - kom tshem tawm cov roj thiab txias - tshuab cov roj ntau dhau ntawm qhov chaw, thiab txias tag nrho cov qos yaj ywm chips kom lawv nkag mus rau hauv lub tshuab tsw qab.

11. Lub tub yees qhov av - khov cov qos yaj ywm sai sai kom lawv cov xim thiab saj.

12. Lub tshuab ntim khoom - raws li qhov hnyav ntawm cov neeg siv khoom ntim khoom, ntim cov qos yaj ywm tsis siv neeg.

Cov qos kib kib sai, cov qos kib kib khov, cov qos kib ib nrab tiav, cov khoom noj txom ncauj qos kib